shop drawings definition engineering

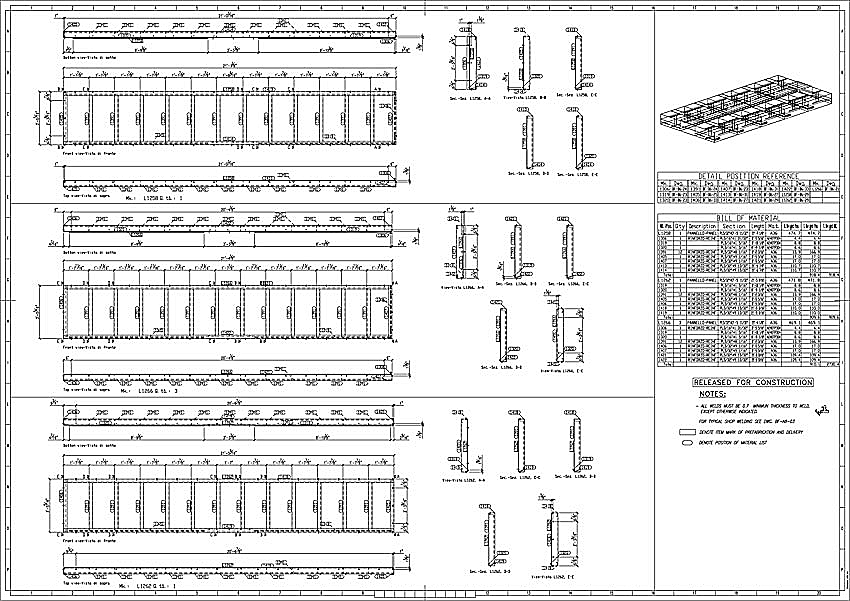

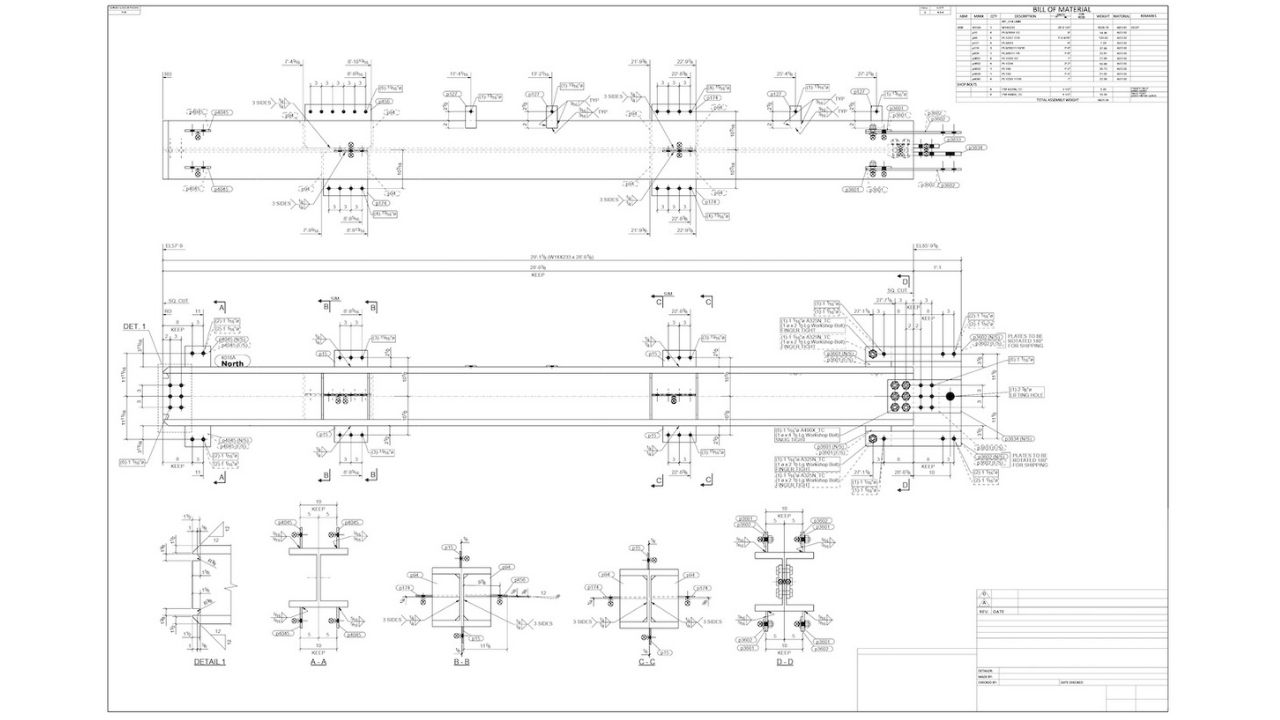

Shop drawings are typically required for pre-fabricated components. An engineering design is usually defined by many individual detail drawings which combine to form an assembly drawing.

Shop Drawings Definition Use Examples Software Alternatives

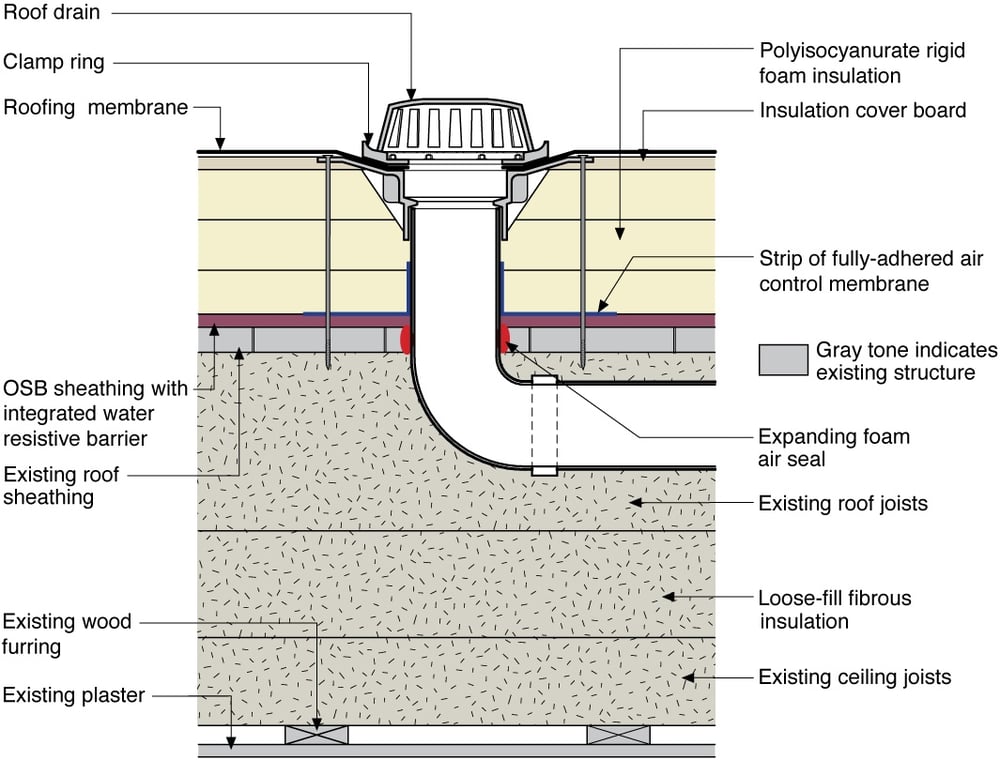

This makes understanding the drawings simple with little to no personal interpretation possibilities.

. Examples of these include. Shop drawings also known as technical drawings are drawings or sets of drawings created by fabricators contractors subcontractors manufacturers or suppliers. The purpose of the shop drawings is to provide the contactor with sufficient detail to make certain that the items set forth in the shop drawings are properly and safely constructed.

Engineering drawings use standardised language and symbols. This requires us to prepare shop drawings which consist of erection drawings and fabrication drawings. Shop drawings or workshop drawings might be prepared by contractors subcontractors suppliers manufacturers or fabricators.

Usually a number of drawings are necessary to completely specify even a simple component. Storefronts Curtain Walls Windows and many other Glass Glazing products etc. Detail drawings seldom describe the intent of an engineering design.

Elevators structural steel trusses pre-cast windows appliances cabinets air handling units and millwork. They generally relate to pre-fabricated components showing how they should be manufactured or installed. A shop drawing is a drawing or set of drawings produced by the contractor supplier manufacturer subcontractor or fabricator.

Shop drawings are typically required for prefabricated components while Design Drawing are the preliminary drawing which could be sketch or pattern aimed for the specific purpose. It has become very common for the type of material we supply to see specificatons which require the submital of certified shop drawings. A shop drawing is a drawing set of drawings produced by the contractor check Examples of these include.

Shop drawings are prepared by fabricators suppliers equipment manufacturers sub-contractors and contractors or by others retained by these parties. Shop drawings - Designing Buildings - Share your construction industry knowledge. Shop drawings are prepared following a review of the drawings specifications and contract documents supplied by the registered professional of record and other project consultants as.

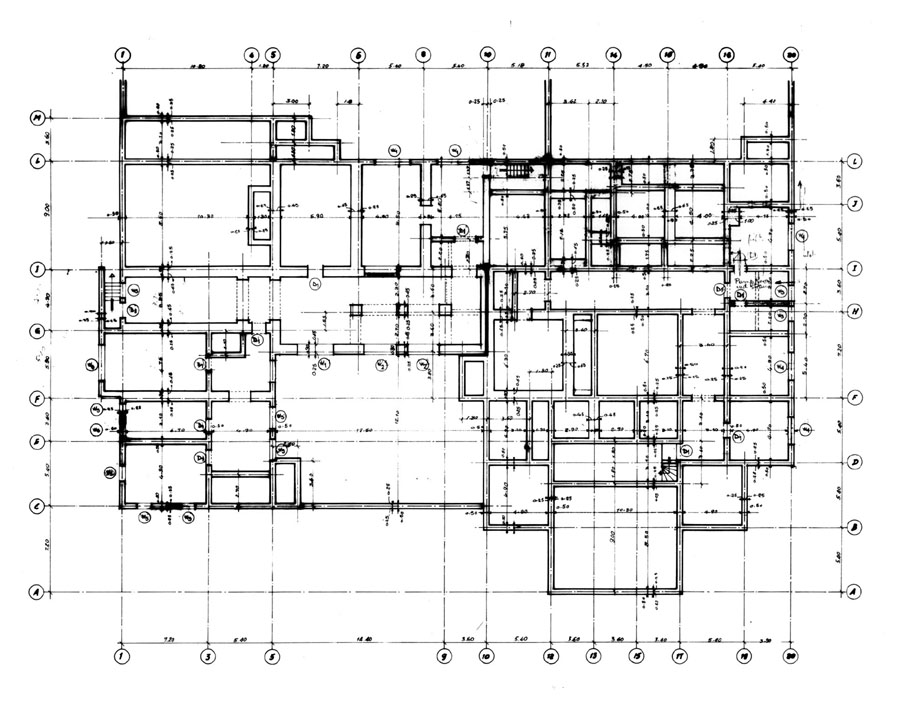

A common use is to specify the geometry necessary for the construction of a component and is called a detail drawing. Engineering drawings are the industrys means of communicating detailed and accurate information on how to fabricate assemble troubleshoot repair and. Shop Drawing or field drawing means a drawing prepared by a contractor subcontractor or vendor that shows how a particular aspect of the work is to be fabricated and installed and demonstrates how an aspect of the work will satisfy the requirements of the construction document but does not include a final drawing specification survey plat plate report or other.

An engineering drawing is a subcategory of technical drawings. The American Institute of Architects AIA family of contracts defines shop drawings as drawings diagrams schedules and other data specially prepared by a distributor supplier manufacturer subcontractor or contractor to show some part of the work. What are Shop Drawings.

They typically include plans elevations views sections and several other details. The name and or drawing number of the assembly drawing in which the detail drawing is called up or used on is stated in the title block. Elevators structural steel trusses pre-cast concrete windows appliances cabinets air handling units and millwork.

An engineering drawing is a type of technical drawing that is used to convey information about an object. A shop drawing is a drawing or set of drawings produced by the contractor supplier manufacturer subcontractor or fabricator. Typically Architectural Shop Drawings are described as a set of drawings produced by the contractor supplier manufacturer subcontractor or fabricator.

The purpose is to convey all the information necessary for manufacturing a product or a part. Shop Drawings means drawings submitted to the PHA by the Contractor subcontractor or any lower tier subcontractor showing in detail 1 the proposed fabrication and assembly of structural elements and 2 the installation ie form fit and attachment details of materials of equipment. Shop drawings are an essential element to many projects providing detail as to how particular elements of a project are to be constructed and installed.

Examples of these components include. Shop drawings are typically required for prefabricated components. They are also required for prefabricated components.

Some specifications will require that all shop drawings be certified and others will only require certification of shop.

Working Drawing Designing Buildings

Shop Drawings Definition Use Examples Software Alternatives

Shop Drawings Definition Use Examples Software Alternatives

Mep Shop Drawing Detailing Services Fulfill The Needs Of Mechanical Electrical And Plumbing Requirements Shop Window Design Diagram Architecture Bim Model

What Is Engineering Drawing Different Types Of Lines In Engineering Drawing Cnclathing

Difference Between Shop Drawings And As Built Drawings

Engineering Drawing Views Basics Explained Fractory

The Difference Between Design Drawings And Shop Drawings

Electrical Shop And Fabricatrion Drawings Advenser

What Is Shop Drawings Why Is It Important

Mep Shop Drawings What Are They And What Are Their Benefits

Shop Drawings Of Construction Project I Type Of Shop Drawings Iram Hameed Rather Youtube

Engineering Drawing Views Basics Explained Fractory

Ifc And Shop Drawing Extraction Vdc Services

Asme Standards For The Revision Of Engineering Drawings Owlcation